You see transformers inside inverters and UPS systems. You're curious about their specific role in converting and managing electrical power for these critical devices.

Transformers in inverters and UPS systems step up or step down voltage. They also provide isolation between the input and output, enhancing safety and power quality.

In an inverter, a transformer typically steps up the low DC voltage (from batteries) after it's converted to AC, to the standard mains AC voltage. In a UPS, transformers can also provide voltage regulation, isolation, and step-up/step-down functions for both input and output power.

At DAOPULSE, with our decade of manufacturing experience, we know transformers are unsung heroes in power electronics. My core insight is that the range of applications for uninterruptible power supplies is very broad, covering industrial fields, home environments, and more. Transformers are key to adapting power for these diverse needs. Let's explore their vital functions.

What is inverter and UPS?

You often hear "inverter" and "UPS" used, sometimes interchangeably. You want to clearly understand the difference and specific purpose of each device.

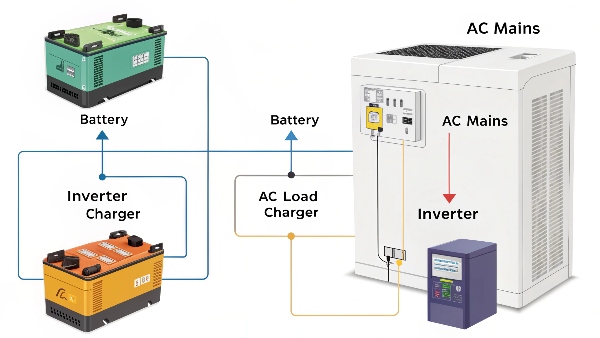

An inverter converts DC power to AC power. A UPS is a complete system that includes an inverter, battery, charger, and transfer switch to provide backup power.

While both involve converting DC to AC, they serve distinct primary roles:

-

Inverter:

- Core Function: To change direct current (DC) from a source like a battery or solar panel into alternating current (AC) suitable for powering standard appliances.

- Components: Primarily consists of switching circuitry (like transistors) that "chop" the DC into a waveform that approximates AC, and often a transformer to step up the voltage.

- Use Cases: Solar power systems, car power inverters (to run AC devices from a car battery), standalone off-grid power.

-

UPS (Uninterruptible Power Supply1):

- Core Function: To provide continuous, clean power to connected equipment during a mains power failure, and often to protect against other power anomalies.

- Components: A UPS is a more comprehensive system that includes an inverter, but also:

- A battery to store energy.

- A battery charger to keep the battery charged from the AC mains.

- A transfer switch to automatically switch between mains power and battery/inverter power.

- Often, filters and surge protection2.

- Use Cases: Protecting computers, servers, medical equipment, telecom systems, and any critical load from power interruptions.

My insight is that the range of applications for uninterruptible power supplies is very broad. An inverter is a key component often found within a UPS. Think of it this way: all UPS systems contain an inverter (to provide AC from the battery), but not all inverters are part of a complete UPS system.

Why is an electromagnetic relay not used in UPS?

You know relays are used for switching. You wonder why modern UPS systems often use solid-state components instead of traditional electromagnetic relays for critical power transfers.

Electromagnetic relays are slower, have mechanical wear, and can create more electrical noise than solid-state switches (like SCRs or IGBTs) used in modern UPS for fast, reliable power transfer.

While some very basic or older UPS designs might have incorporated electromagnetic relays for certain functions, modern UPS systems, especially those designed for critical applications, predominantly use solid-state switching components (like Silicon Controlled Rectifiers - SCRs, Insulated Gate Bipolar Transistors - IGBTs, or MOSFETs) for key power path switching. Here's why:

- Switching Speed: Solid-state switches are significantly faster. A typical UPS needs to transfer from mains to battery power in milliseconds (often 2-10ms) to prevent connected IT equipment from rebooting. Relays have a mechanical action that introduces delays (tens of milliseconds) which can be too slow.

- Reliability and Lifespan: Relays have moving parts that are subject to wear and tear, arcing, and eventual failure. Solid-state switches have no moving parts, leading to much higher reliability and a longer operational lifespan, crucial for a device meant to ensure uptime.

- Electrical Noise (EMI): The arcing across relay contacts as they open or close can generate significant electromagnetic interference (EMI), which can disrupt sensitive electronic equipment that the UPS is supposed to protect. Solid-state switches can be designed for "softer" switching with less EMI.

- Size and Efficiency: Solid-state components can be more compact and, when properly designed, can offer higher efficiency than relays, especially in high-power applications.

- Control Precision: Solid-state devices allow for more precise control over the switching process, enabling features like synchronized transfers which are smoother for the load.

My insight is that the range of applications for uninterruptible power supplies is very broad, covering industrial fields, home environments, and more. The demand for seamless, reliable power in these applications necessitates the speed and durability of solid-state technology over older relay-based designs for critical path switching. Relays might still be found in a UPS for non-critical functions, like signaling or controlling auxiliary circuits, but not usually for the main power transfer.

How does inverter technology work in air conditioners?

You see "inverter air conditioner" advertised. You want to understand how this "inverter technology" differs from traditional ACs and what benefits it offers.

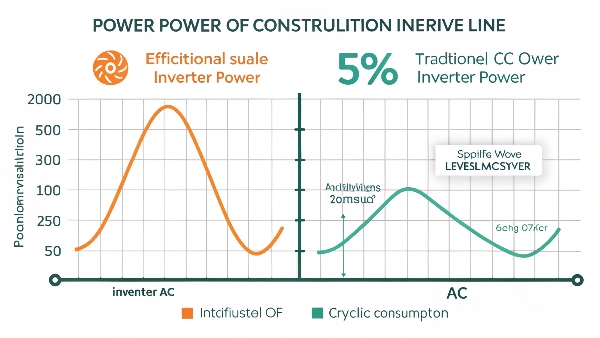

Inverter ACs use a variable-speed compressor controlled by an inverter. This allows the AC to precisely match cooling output to demand, saving energy and improving comfort.

Traditional air conditioners use a single-speed compressor. It's either fully ON (cooling at maximum capacity) or fully OFF. This leads to:

- Temperature fluctuations as the room cools down, then warms up before the AC kicks back on.

- High energy consumption due to frequent starts and stops of the compressor (which draws a lot of current on startup).

Inverter technology in an air conditioner revolutionizes this by using an inverter (DC-to-AC converter) to control the compressor motor's speed:

- AC mains power is first converted to DC.

- This DC power then goes to an inverter module.

- The inverter converts the DC back to AC, but at a variable frequency and voltage.

- This variable AC power is fed to the compressor motor, allowing its speed to be precisely controlled.

Benefits:

- Energy Efficiency: The compressor runs at the exact speed needed to maintain the set temperature, rather than constantly cycling on and off at full power. This significantly reduces energy consumption, often by 30-50%.

- Precise Temperature Control: The AC can make fine adjustments to its cooling output, leading to more stable and comfortable room temperatures without noticeable swings.

- Quieter Operation: Because the compressor doesn't always run at full speed and avoids hard starts/stops, inverter ACs are generally much quieter.

- Faster Cooling/Heating: When first turned on, the inverter can run the compressor at a higher-than-normal speed to reach the desired temperature more quickly.

- Longer Component Life: Reduced stress from frequent starts and stops can lead to a longer lifespan for the compressor.

My insight is that the range of applications for uninterruptible power supplies (and inverters as a core component) is very broad. While a UPS uses an inverter to create backup AC power from a battery, an inverter AC uses similar technology to efficiently control its motor for climate control.

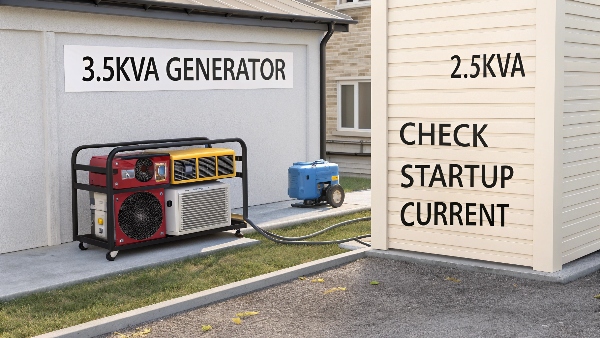

Can a 3.5kva generator power a 2.5kva AC?

You have a 3.5kVA generator and a 2.5kVA air conditioner. You're trying to figure out if the generator is sufficiently powerful to run the AC unit reliably.

Likely yes, a 3.5kVA generator should power a 2.5kVA AC, but check the AC's startup (LRA) current and the generator's surge capacity. AC units draw much more power when starting.

On the surface, a 3.5kVA (kilovolt-ampere) generator seems adequate for a 2.5kVA air conditioner, as 3.5 is greater than 2.5. However, there are critical factors to consider, especially with motor-driven appliances like air conditioners:

-

kVA vs. kW (Kilowatts):

- kVA is "apparent power." kW is "real power" (the power that does actual work).

- Generators are often rated in kVA. AC units are sometimes rated in kVA, sometimes in kW, or by BTU (which can be converted to kW).

- The relationship is kW = kVA Power Factor (PF). For resistive loads, PF is 1 (kVA=kW). For motors, PF is less than 1 (e.g., 0.8). If your AC is 2.5kVA and has a PF of 0.8, its real power draw is 2.5 0.8 = 2kW.

- Ensure your generator's continuous kW output (if specified, otherwise estimate using a typical PF of 0.8 for the generator itself, so 3.5kVA * 0.8 = 2.8kW) can handle the AC's running kW.

-

Startup Current (Inrush Current / Locked Rotor Amps - LRA):

- This is the most critical factor. Air conditioner compressors draw a very large surge of current for a few seconds when they start, often 3 to 8 times their normal running current.

- Your 3.5kVA generator must be able to supply this peak startup current without stalling or tripping its breaker. Check the AC's nameplate for LRA or startup amps. Check the generator's manual for its peak/surge wattage or amperage capacity.

- If the generator's surge capacity is insufficient, it won't be able to start the AC.

-

Generator Quality and Type:

- Inverter generators are generally better at handling sensitive electronics and can sometimes manage inrush currents more smoothly due to their electronics.

- Conventional generators might struggle more if not generously oversized.

General Guideline: For air conditioners, it's often recommended to have a generator with a continuous running capacity at least 2-3 times the AC's running wattage to reliably handle startup.

- If 2.5kVA is the AC's running load, and assuming a PF of 0.8, that's 2kW.

- Your 3.5kVA generator (approx. 2.8kW continuous at PF 0.8) might be just enough if its surge capacity is good.

My insight is that while the range of applications for uninterruptible power supplies and power generation is broad, matching sources to loads requires careful consideration of peak demands, not just continuous ratings. It's best to consult the manuals for both your AC and generator regarding startup current requirements and surge capacity.

Conclusion

Transformers are crucial in inverters and UPS systems for voltage adjustment and isolation. Understanding the distinction between an inverter and a full UPS, and why modern UPSs prefer solid-state switches, clarifies their design for reliable power.