Harsh industrial sites suffer costly shutdowns from power blips. Standard office UPS units often fail fast in tough conditions. Industrial UPS systems offer rugged, reliable backup power designed to withstand these demanding environments.

An industrial UPS system is a specially designed uninterruptible power supply built to operate reliably in harsh environments like factories, power plants, or outdoor installations. It features enhanced durability, wider operating temperatures, and robust components.

The industrial sector definitely needs more robust uninterruptible power supplies than a typical office. At DAOPULSE, with our 10 years of experience as an OEM/ODM manufacturer, we've seen firsthand how critical reliable power is in these settings. We have UPS systems specifically designed for industrial applications. We don't just sell a box; we provide complete packaged systems tailored to unique challenges. Procurement managers for manufacturing plants or system integrators for infrastructure projects often come to us because they need solutions that can handle dust, vibration, extreme temperatures, and fluctuating power quality. They need assurance that the UPS will perform, and our comprehensive testing and certifications like CE, RoHS, and ISO provide that confidence.

What is the difference between commercial UPS and industrial UPS?

Choosing between commercial and industrial UPS units can be confusing. Picking the wrong one leads to premature failure in harsh settings or overspending on features you don't need for an office.

Industrial UPS systems are built for harsh environments with wider temperature ranges, better protection against dust/moisture, and more robust components. Commercial UPS units are designed for controlled, clean office-like environments.

The differences between commercial and industrial UPS systems are significant. They are designed for very different operating conditions and performance expectations. I often explain to clients that it's like comparing a family sedan to an off-road, heavy-duty truck. Both provide transport, but they are built for vastly different terrains and tasks.

Environmental Hardening:

- Industrial UPS: Designed to operate in wider temperature ranges (e.g., -20°C to +55°C or even wider). They often feature sealed enclosures (like NEMA or IP rated) to protect against dust, moisture, corrosive elements, and vibrations. Their internal components are often conformally coated.

- Commercial UPS: Designed for clean, climate-controlled environments, typically 0°C to 40°C. They offer little protection against contaminants.

Component Grade and Design Life:

- Industrial UPS: Use higher-grade, more durable components designed for a longer operational life (often 15-20 years or more). They anticipate more severe electrical disturbances like surges and transients.

- Commercial UPS: Use components suited for a less demanding environment, with a typical design life of 5-10 years.

Input/Output Voltage and Isolation:

- Industrial UPS: Often require greater flexibility in input voltage ranges and may include input/output isolation transformers for enhanced protection and voltage matching in challenging electrical environments. They might also support specific industrial DC voltages.

- Commercial UPS: Usually designed for standard utility voltages with less emphasis on extreme voltage tolerance or isolation.

At DAOPULSE, our UPS design and customization services excel here. We tailor our industrial UPS solutions, whether lead-acid or lithium battery based, to meet specific client requirements for harsh conditions, ensuring they get a system that truly lasts.

| Feature | Commercial UPS | Industrial UPS |

|---|---|---|

| Operating Environment | Clean, office-like (0-40°C) | Harsh, wide temps, dust, moisture (-20°C to 55°C+) |

| Enclosure | Standard, open ventilation | Sealed (NEMA/IP rated), ruggedized |

| Component Grade | Standard | Heavy-duty, long-life, often conformal coated |

| Design Life | 5-10 years | 15-20+ years |

| Vibration Resistance | Low | High |

| Electrical Isolation | Basic or none | Often includes isolation transformers |

| Cost | Lower | Higher |

What is an example of a UPS system?

UPS systems sound complex and abstract if you're unfamiliar. Without a clear picture, it's hard to see how they actually work or fit into real-world power protection needs.

A common example is a small Standby UPS under a home office desk, protecting a PC. It keeps the computer running for a few minutes during a blackout, allowing safe shutdown.

A UPS system, at its core, is a device that provides emergency power to a load when the input power source, typically utility mains, fails. But the type and scale can vary dramatically. Here are a few examples to illustrate:

-

Home Office Standby UPS:

- Type: Standby (Offline) UPS.

- Application: A small unit, perhaps 500VA to 1500VA, sitting under a desk. It powers a personal computer, monitor, and maybe a modem/router.

- Function: When a blackout occurs, it instantly switches to its internal battery, providing power for 5-15 minutes. This gives the user enough time to save their work and shut down the computer gracefully, preventing data loss or hardware corruption. It also offers basic surge protection.

-

Small Business Line-Interactive UPS:

- Type: Line-Interactive UPS.

- Application: A rack-mounted or tower unit, perhaps 2kVA to 5kVA, in a small server closet. It powers a couple of servers, a network switch, and a storage device.

- Function: This UPS not only protects against blackouts but also uses its Automatic Voltage Regulator (AVR) to correct common brownouts (low voltage) and swells (high voltage) without switching to battery. This prolongs battery life and provides cleaner power to sensitive IT equipment. Our lithium battery UPS solutions are becoming popular here for their longer life and better power density.

-

Industrial Process Control Online UPS:

- Type: Online (Double-Conversion) Industrial UPS.

- Application: A robust, large kVA system (e.g., 50kVA three-phase) installed in a manufacturing plant's control room or powering a critical piece of automated machinery.

- Function: This UPS constantly regenerates clean, stable power from the utility input, completely isolating the sensitive control systems or machinery from all power disturbances – sags, swells, noise, frequency variations, and blackouts. There's zero transfer time. These systems are built to withstand harsh industrial environments (dust, temperature extremes) and often feature our patented technology for enhanced reliability and efficiency. This is a core area for DAOPULSE, where we provide expert design and comprehensive testing.

These examples show the versatility of UPS systems, from basic home use to mission-critical industrial applications. The choice always depends on the load's sensitivity and the environment.

What is the difference between UPS and inverter?

People often use "UPS" and "inverter" interchangeably. This common confusion can lead to buying the wrong device if you're not clear on their distinct primary functions and capabilities.

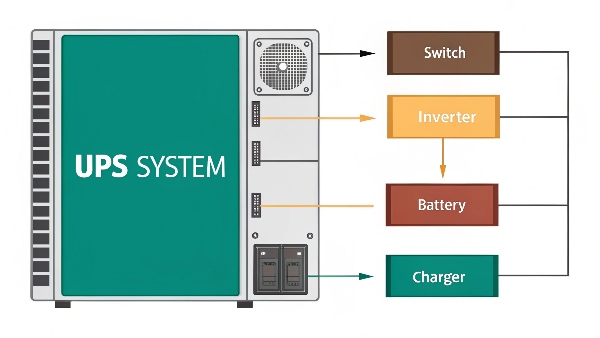

An inverter's primary job is to convert DC power to AC power. A UPS is a complete system that includes an inverter, battery, charger, and control logic to provide backup power.

It's a very common point of confusion. An inverter is a key component of a UPS, but a UPS is a much more comprehensive system. Think of it this way: an engine is a key part of a car, but a car is much more than just an engine.

Inverter:

- Primary Function: To convert Direct Current (DC) power into Alternating Current (AC) power.

- How it works: Takes DC voltage (e.g., from a battery or solar panel) and changes it into AC voltage (e.g., 120V or 230V AC like your wall outlet).

- Standalone Use: You can buy standalone inverters. For example, people use them in vehicles to power AC appliances from the car's DC battery, or in off-grid solar power systems.

- Limitations: A basic inverter on its own doesn't typically charge batteries, switch automatically when mains power fails, or provide power conditioning (like voltage regulation or surge protection) unless these features are specifically built into a more advanced inverter/charger unit.

UPS (Uninterruptible Power Supply):

- Primary Function: To provide continuous, high-quality power to connected equipment, protecting it from power outages and various power quality problems.

- Key Components:

- Rectifier/Charger: Converts incoming AC utility power to DC to charge the batteries and, in an Online UPS, to power the inverter.

- Batteries: Store energy to be used during a power outage. We offer both lead-acid battery UPS solutions and lithium battery UPS solutions.

- Inverter: Converts DC power from the batteries (or rectifier) back to clean AC power for the connected load.

- Static Switch/Transfer Switch: Automatically switches the load between utility power and battery/inverter power (in Standby and Line-Interactive types) or between bypass and inverter (in Online types).

- Control Logic: Manages the operation, monitoring, and protection features.

- Additional Features: UPS systems often include surge protection, noise filtering, and (in Line-Interactive and Online types) voltage regulation. Our patented technology development often enhances these features.

Essentially, a UPS is a sophisticated system designed for seamless power backup and protection, and an inverter is one of the critical building blocks within that system. As an OEM/ODM manufacturer, [Your Company Name] designs the entire UPS system, carefully selecting and integrating all components, including the inverter, to meet specific performance and reliability standards required by clients, such as procurement managers in critical industries.

| Feature | Inverter | UPS System |

|---|---|---|

| Main Purpose | Converts DC to AC | Provides uninterruptible power & protection |

| Components | Primarily DC-to-AC conversion electronics | Inverter, battery, charger, transfer switch, control logic, filtering, etc. |

| Battery Mgmt. | Not inherent (unless an inverter/charger) | Yes, includes charging and management |

| Auto Transfer | No (unless specifically designed to) | Yes, automatic switch to battery on power failure |

| Power Cond. | Minimal (waveform quality depends on type) | Often includes surge, noise, voltage regulation (type-dependent) |

| Completeness | A component or basic device | A complete, integrated system solution |

What are the different UPS configurations?

Thinking a UPS is just a single box limits your options. Ignoring different UPS configurations can lead to inadequate protection, poor scalability, or unnecessary downtime if a single unit fails in a critical setup.

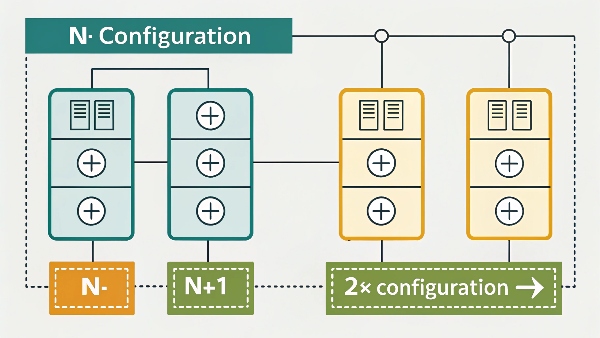

Common UPS configurations include Standalone (N), Parallel Redundant (N+1, N+X) for increased capacity/reliability, and Dual Bus (2N, 2N+X) for ultimate fault tolerance, especially in critical industrial and data center environments.

When we talk about UPS configurations, especially for critical applications like those in industry or data centers, we're referring to how multiple UPS units (or modules within a larger system) are arranged to provide power, enhance reliability, and allow for maintenance. Choosing the right configuration is key for meeting availability targets.

Here are the main configurations:

-

Standalone (N Configuration)1:

- This is the simplest setup, where a single UPS unit (or a single string of modules) is sized to support the total critical load. 'N' represents the capacity needed to power the load.

- Pros: Most cost-effective, simple to install.

- Cons: No redundancy. If the UPS fails or needs maintenance, the critical load loses power or must be transferred to raw utility power (if a bypass is available), which offers no protection. Not suitable for truly critical industrial processes.

-

Parallel Redundant (N+1, N+X Configuration)2:

- Multiple UPS units (or modules) are connected in parallel. The total capacity of the UPS system is greater than what the critical load requires.

- N+1: One extra UPS unit/module beyond what's needed (N). For example, if the load is 100kVA, you might use two 100kVA UPS units in parallel, or a modular system with three 50kVA modules. If one unit/module fails or is taken offline for maintenance, the remaining unit(s) can still support the full critical load.

- N+X: More than one redundant unit/module (e.g., N+2).

- Pros: Significantly improves availability and allows for concurrent maintenance.

- Cons: Higher cost than N.

- This is a very common approach for industrial applications where high uptime is essential. Our UPS design and customization capabilities allow for flexible N+1 solutions.

-

Dual Bus / Distributed Redundant (2N, 2N+X Configuration)3:

- This is the highest level of redundancy. It involves two independent UPS systems (each potentially N or N+1 capable on its own), each feeding a separate power path to the critical load. The load equipment must have dual power supplies (common in enterprise-grade servers and some industrial controllers) to connect to both power paths.

- 2N: Two completely independent power paths, each capable of powering 100% of the load.

- 2N+X: Adds further redundancy within each of the two buses.

- Pros: Extremely high availability. Fault tolerant to an entire UPS system failure or even a failure in one power distribution path. Allows for extensive maintenance without impacting the load.

- Cons: Most expensive and complex. Requires dual-corded loads.

- Essential for mission-critical facilities where any downtime is unacceptable.

At DAOPULSE, our team, with its extensive expertise in UPS technology, works closely with clients like system integrators and procurement managers to determine the optimal configuration. We consider their risk tolerance, budget, and the criticality of their operations, ensuring our advanced facilities produce the right range of UPS systems, from small-batch trials to full-scale manufacturing of modular, redundant systems designed for industrial resilience.

Conclusion

Industrial UPS systems offer vital, rugged power protection. Understanding their specific design, examples, configurations, and how they differ from commercial units or simple inverters ensures optimal reliability for demanding environments.

-

Discover the advantages and limitations of Standalone UPS setups to make informed decisions for your power needs. ↩

-

Explore this link to understand how Parallel Redundant configurations enhance reliability and uptime for critical applications. ↩

-

Learn about Dual Bus configurations to see how they provide the highest level of redundancy and fault tolerance for critical systems. ↩